The goal of our Know Your Fibers series is to provide info about different types of fibers for our readers. In this post, we’ll take a look at how nonwovens compare to woven and knit fabrics.

Just by using the word nonwoven, you know a nonwoven fabric is not a woven fabric. It is also not a knit fabric. While production of nonwoven fabrics only requires a few steps, production of woven or knitted fabrics requires that the fibers be made into yarn first—then those yarns must be woven or knitted into fabrics. Conventional textiles like clothing, sheets, towels, upholstery, and curtains are made from woven knitted fabrics.

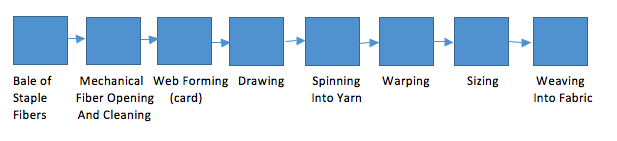

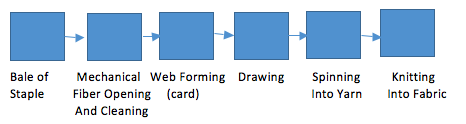

Let’s look at the different production steps for each respective fabric:

Production of Nonwoven Fabrics from Staple Fibers

Production of Woven Fabrics from Staple Fibers

Production of Knit Fabrics from Staple Fibers

As you can see from the diagrams, producing nonwoven fabrics has fewer steps than woven or knit fabrics. Also, the production speed for making staple fiber nonwoven fabrics is much faster (100 to 400 yards per minute) than woven fabrics (0.5 to 6 yards per minute) and knit fabrics (2 to 16 yards per minute). Because of the higher speeds and reduction of steps, nonwoven fabrics cost much less to produce.

Nonwoven Fabrics Breakdown

The fibers are bonded together by mechanical bonding (fiber entanglement), chemical bonding (fibers are chemically bonded together with glue-like compounds), or thermal bonding (where low-melt fibers are used and heat is used to melt the fiber to each other). Nonwoven fabrics are lighter and weaker than woven or knit fabrics. They don’t have much memory (for example, if you bend your elbow the fabric will retain that position and leave a pucker in the fabric) or laundering durability, making them unsuitable in durable clothing applications. Since they are cheap to produce, they’re ideal for single-use products such as wipes, medical products, feminine hygiene products disposable diapers, etc.

Woven Fabrics Breakdown

Woven fabrics are produced on a loom. The loom joins two sets of yarns by weaving one set between the other. The two sets of yarns are perpendicular to each other. One set is called the warp and runs the length of the fabric. The loom will raise some other warp yarns up and some down, ultimately creating a shed. The fill or weft yarn is placed in the shed parallel to the ward yarn and the shed closes. Now the yarns that were down go up, and the ones that were up go down, creating another shed as another fill yarn is put through. Many different fabric constructions (like plain weave, twill weave, etc.) can be created by changing which yarns are opened up or pulled down in the shed. Woven fabrics are durable to washing and can be finished to yield many different properties (like being flame-retardant or water-repellant). They do not have much stretch because of the tightness of the yarns in the fabric. Yarn properties are important for the fabric’s performance. If you want a more stretchy fabric you can add some elastomeric fibers (think Spandex) to the yarn.

Knit Fabrics Breakdown

Knitting is defined as forming a fabric by means of interloping the yarn. Knitting machines do the same interloping of yarn that a hand knitter does. Knit fabrics have stretch because of the looseness of the fabric’s yarn structure (compared to knits and most nonwovens). Because of this looseness, the fabric can tighten up due to the mechanical action in laundering. That’s why knit fabrics shrink. Most current knit fabrics are pre-shrunk before a garment is made from them, which eliminates most shrinkage. Because the yarns in knit fabrics are looped around themselves, if you pick a knit fabric the whole length of that course of yarn will unravel. I’m sure you have seen this happen before. Knit fabrics are comfortable and warm, which explains why many sweaters are made from them.

As you can see, there are many differences in these fabrics and there are many uses for each type. The pie in the sky is to produce a comfortable garment of nonwoven fabrics that will be durable, as well as more economical to produce. This has not yet been accomplished—but there’s always hope.