Excellence That Begins at the Source

Rooted In Responsibility

We partner with the industry's top cotton growers, ginners, and suppliers to ensure the responsible sourcing of raw materials while driving positive environmental and social outcomes. By prioritizing sustainability, traceability, and ethical practices, we uphold our values and deliver responsibly sourced, high-quality cotton to our customers.

Purity Standard

At Barnhardt, purity isn’t just a standard—it’s the foundation of everything we do. Through decades of research-driven innovation, we have redefined cotton processing to deliver fibers that are cleaner, safer, and more sustainable. Our meticulous approach ensures that every step, from raw material selection to final purification, upholds the highest quality and environmental standards.

From pioneering the chlorine-free Totally Chlorine-Free (TCF) process to developing our industry-first Enhanced Visual Opening Cleaning (EVOC) System, we have set new benchmarks in cotton purification. EVOC’s advanced mechanical cleaning and whitening process removes impurities, enhances fiber quality, and achieves an unprecedented level of purity. Designed for next-to-skin applications, our cotton meets the most rigorous standards for medical and personal care products, ensuring both safety and performance.

Backed by rigorous testing, continuous improvement, and a commitment to sustainability, our custom cotton solutions provide unparalleled quality and reliability. Whether for hygiene, healthcare, or specialty applications, Barnhardt cotton is trusted worldwide—because better cotton starts with a better process.

Cotton Processing

Barnhardt cotton undergoes an extensive purification process to meet our exacting standards for quality, safety, and performance. Raw cotton arrives in densely packed bales, but harvesting methods are imperfect. Despite the efforts of cotton gins, these bales still contain field debris, plant matter, and dirt. Additionally, cotton fibers are naturally coated with wax, making them completely hydrophobic, and they carry a subtle yellow tint. These factors make raw cotton unsuitable for use in many consumer products where absorbency and whiteness are critical in many applications.

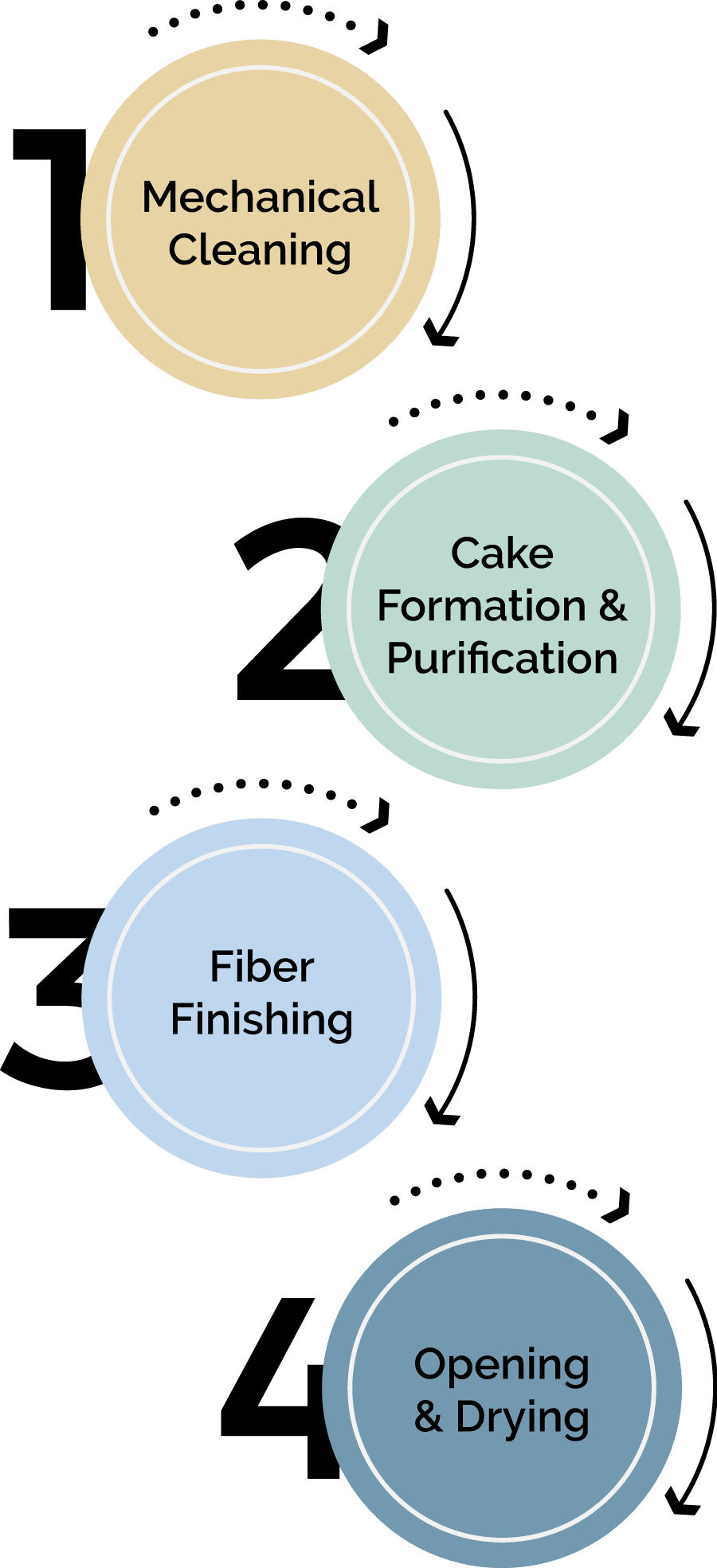

Step 1: Mechanical Cleaning

To begin the process, multiple raw cotton bales are laid out in a single layer. Thin layers are gradually pulled from each bale and combined to produce a uniform fiber stream, which is then fed into a hopper that pulls the dense tufts apart into more open material. The opened cotton then moves through a series of highly advanced cleaning technologies, known as the EVŌC system (Enhanced Visual, Opening, Cleaning system). This system removes much of the plant matter—such as stalks, stems, and leaves—as well as extraneous matter and trash.

Step 2: Cake Formation and Purification

After mechanical cleaning, the cotton is wet out and packed into large cakes. These cakes are then lowered down into kiers— pressurized vessels that use water to help transport purification chemicals through the cotton. Inside the kier, the cotton undergoes our certified Totally Chlorine Free (TCF) purification process, which oxidizes the colored matter and removes undesired substances of interest (SOIs) and foreign matter. Combining oxidation with the purification process results in a white fiber that meets the performance, quality, and safety standards for which Barnhardt is known.

Step 3: Fiber Finishing

After purification, a finish is often added to the cotton while it is in the kier. This finish reduces friction between the fibers, allowing for more efficient processing on high-speed equipment. Many types of finishes can be applied depending on the desired final properties, and the level of finish is closely monitored to ensure optimal fiber performance.

Step 4: Opening and Drying

After completing its journey through the kier, the cotton is carefully removed, and each cake undergoes hydro-extraction to eliminate excess water. The compressed cakes are then broken into soft tufts of fiber, which are dried to the perfect moisture level. Once dried, the fibers pass through advanced cleaning equipment to remove any remaining impurities before being baled and securely strapped. A unique bale label is then applied, marking the cotton’s final step before rigorous quality testing ensures it meets our high standards. Only then is it ready to be shipped to customers around the world.

Safety-First Culture

Journey to Zero

Learn MoreAt Barnhardt, we are committed to the highest safety standards, striving for a proactive culture that prevents risks before they occur. Our Journey to Zero focuses on identifying and eliminating hazards rather than reacting to incidents. Through continuous training and improvement initiatives, we ensure operational excellence and the unwavering protection of our workforce, keeping safety at the core of everything we do.