Barnhardt seeks to understand the future implications of our actions by focusing on the economic, social, and environmental impacts of our business.

Sustainability is a Priority for Us and Our Customers

At Barnhardt, we are dedicated to environmentally responsible manufacturing and remain at the forefront of our industry. By leveraging our rich heritage and expertise, we are able to produce purified cotton solutions that set the standard for quality and sustainability. Our commitment extends to advancing agriculture-based innovations that address the growing demand for eco-friendly alternatives.

We recognize that sustainability is a priority for both our company and our customers, who are increasingly focused on environmental health, waste management, and reducing greenhouse gas emissions (GHG). While making sustainable choices can be challenging, Barnhardt remains steadfast in our commitment to delivering the highest-quality cotton while driving meaningful progress in sustainable innovation across our industry.

Industry Standards and Barnhardt Practices

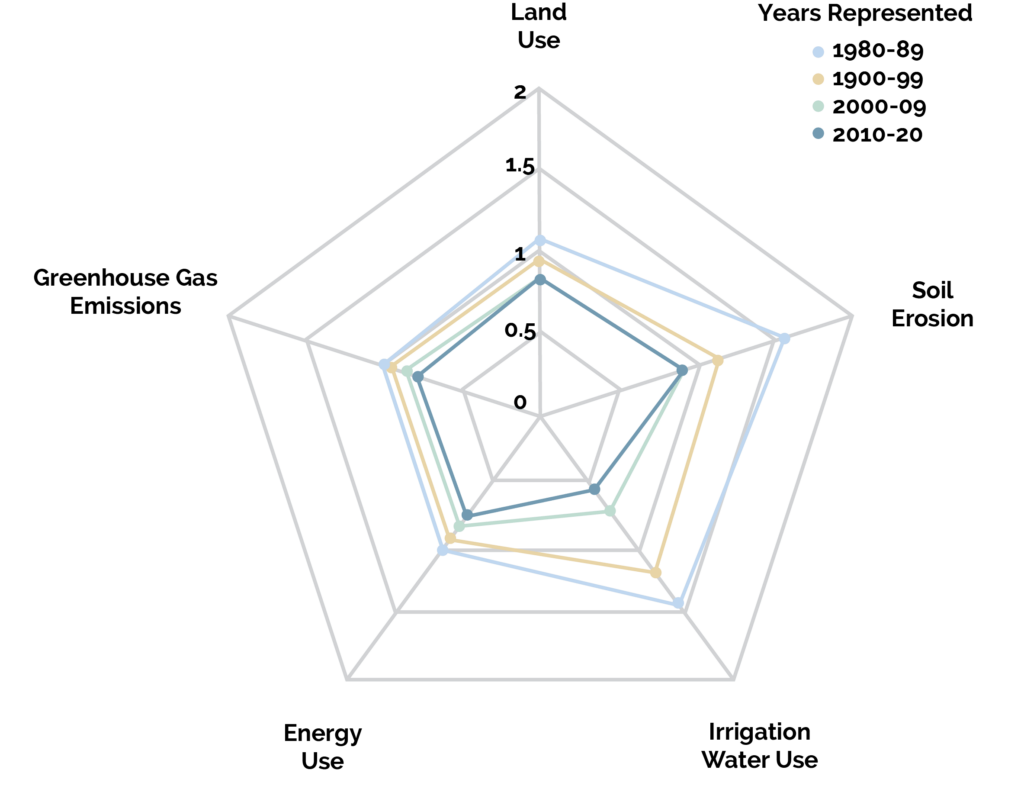

Barnhardt is committed to advancing sustainable growing practices in U.S.-grown cotton, striving for best-in-class standards among our raw material suppliers. By working closely with southern growers, we support high-quality cotton production with a lower environmental footprint. Over our 125-year history, agricultural practices have continually improved, and as the industry shifts toward organic methods, we remain at the forefront—where cotton quality meets sustainable innovation.

Explore the Report

U.S. Field to Market Agricultural Data 1980-2020

Regenerative Agriculture (RA)

We’re not just following national trends in regenerative agriculture (RA); we’re leading the way in the cotton industry and striving to do even better. Partnering with organic suppliers to meet cotton standards is just the beginning—we’re constantly pushing for more. Regenerative agriculture goes beyond organic farming by focusing on enhancing soil health, restoring ecosystems, and improving land over time. By encouraging our suppliers to adopt sustainable practices that promote water retention, carbon sequestration, and nutrient cycling, we’re driving meaningful progress toward a more sustainable future for cotton farming.

Reclamation Initiatives

Barnhardt employs multiple fiber waste reclamation streams, including an internal recycling loop and a dedicated facility for cleaning and repurposing waste fibers, all aimed at achieving zero waste. Our Charlotte, NC, facility features advanced water recycling, reusing over half of its water, and a heat recovery system that reduces natural gas consumption. With just 0.18 tons of waste generated per ton of cotton produced, we treat and repurpose most byproducts as fertilizer or fuel. Additionally, by prioritizing U.S. suppliers, we reduce Scope 3 emissions and support domestic businesses, furthering our commitment to a sustainable future.

Life Cycle Assessment

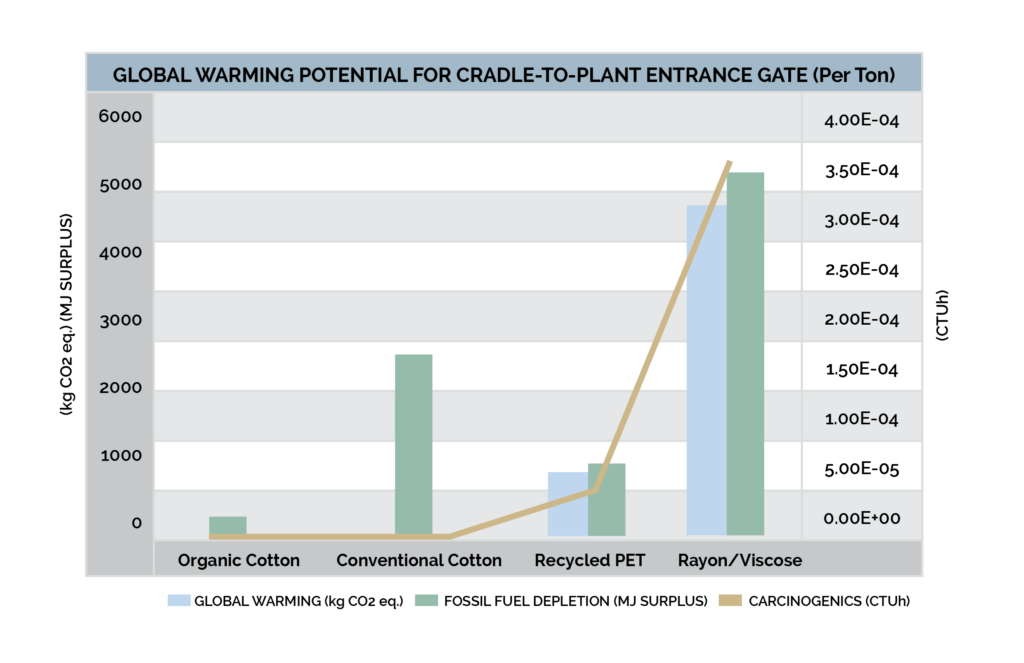

In 2024, Barnhardt partnered with a third-party service to conduct a Screening Life Cycle Assessment (S-LCA) using TRACI 2.1, identifying key areas for environmental improvement. The assessment revealed that raw fiber production is a primary driver of our carbon footprint, highlighting the importance of strengthening partnerships with farmers to adopt sustainable, organic, and regenerative practices to reduce Scope 3 emissions. Cotton, especially organic, is a far more sustainable choice than rayon/viscose and recycled PET, which rely on harmful chemicals and fossil fuels. Organic cotton reduces GHG emissions by 40-50% compared to conventional cotton and avoids contributing to plastic pollution, making it a cleaner, more renewable option.

Barnhardt Raw Materials Compared to Other Fibers