Barnhardt Purified Cotton = USP Purified Cotton. At Barnhardt, we go to great lengths to ensure we provide purified cotton fiber of the highest order. By removing as much foreign matter as humanly possible (raw cotton comes with its fair share of field trash), we ensure a final product that meets the highest standards of quality. Of course, the USP sets standards for purification, so let’s start with understanding exactly what the organization does. Since Barnhardt’s purified cotton meets all of their standards, it will give you a better understanding of the strict requirements behind calling cotton purified.

What Is the USP?

The U.S. Pharmacopeia Convention (USP) is a scientific nonprofit organization that “sets standards for the identity, strength, quality, and purity of medicines, food ingredients, and dietary supplements manufactured, distributed, and consumed worldwide. USP’s drug standards are enforceable in the United States by the Food and Drug Administration (FDA), and these standards are used in more than 140 countries. Europe has the EP group and Japan has its JP group for use in those areas.”

The U.S. Pharmacopeia Convention (USP) is a scientific nonprofit organization that “sets standards for the identity, strength, quality, and purity of medicines, food ingredients, and dietary supplements manufactured, distributed, and consumed worldwide. USP’s drug standards are enforceable in the United States by the Food and Drug Administration (FDA), and these standards are used in more than 140 countries. Europe has the EP group and Japan has its JP group for use in those areas.”

All three groups (USP, EP, and JP) have a monograph for Purified Cotton which has the test methods and test result limits that the fiber must meet to make a pharmacopeia claim. Keep in mind the specifications are slightly different for all three pharmacopeia groups.

What Are the Specific U.S. Requirements?

While Barnhardt’s purified cotton fiber can meet the required specifications set by all three groups, since we’re a U.S. company we’ll focus on the USP requirements:

- Alkalinity/Acidity (pH): The fiber sample is saturated with water and the water is squeezed from the fiber. The water must have no pink color when methyl orange and phenolphthalein indicators are added. This means the pH is in the range of 4.4 to 8.2.

- Residue on ignition (ash): A fiber sample is placed in a dish and saturated with diluted sulfuric, then placed over a flame and heated until the carbon is consumed. By weight, only 0.2% or less of residue can remain.

- Water Solubles: A fiber sample is placed in water and boiled for 30 minutes. The water is filtered to remove the fibers and then evaporated. 0.3% or less residual (by weight) can remain.

- Fatty Matter: The fiber sample is extracted using ether for four hours. The ether is filtered to remove the fiber and then it is evaporated. The residual must be less than or equal to 0.7% by weight.

- Absorbency Time: Purified cotton is required to sink in water in 10 seconds or less.

- Absorbency Capacity: The fiber sample is saturated (submerged) in water and removed. The water held by the fiber must be equal to or greater than 24 times the weight of the fiber. In other words, one gram of fiber must hold 24 grams of water or more.

- Dyes: No blue or green tint in alcohol extract.

We Can Meet Requirements Here and Abroad

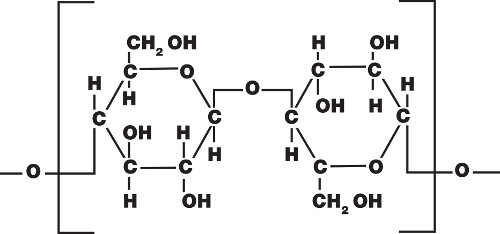

As you can see, in order for cotton to be USP Purified Cotton it has to meet many strict requirements. It is almost pure cellulose. If your products require that the purified cotton must meet USP, EP, or JP specifications, we can definitely produce it. It’s also important to note that not all products require pharmacopeia grade fiber, and that we can supply that as well.